Laughing Mozzie Papier Mache Blog

Crafts-People and Artists

Papier Mache and Paper Mache Clay are most amazing craft materials. This blog is for those who are beyond grade school. We suggest you visit www.papiermache.co.uk/ where you will find all you need to know about papier mache.

2015/11/05

2015/01/28

2012/04/26

Ron Graham - Papier mache puppets

Insights into paper pulp

Casting puppet parts in paper pulp

Creating a puppet head from cast paper pulp parts

Creating the illusion

How to make and use a paper tearing machine .

How to make and use a pulp beater

Puppets exhibited 1

Puppets exhibited 2

Drawings on paper

2011/04/25

Rosette Gault articles on paperclay to download

The Helpful Practical Basics

"how-to" get started with pictures PDF's

==

Rosette Gault Bio:

Rosette Gault, M.F.A Ceramics, has been contributing to

the field of artistic ceramics as a visual artist for over 35 years.

Her award winning ceramic sculpture and commission work has been

exhibited widely since 1978, and is included in public and private

collections in Canada, USA, Italy, Finland, UK, Czech Republic, Denmark,

Hungary, and beyond.

Her books include Paper Clay for Ceramic Sculptors (in print since 1993), and Paper Clay (in print since 1998) co-published

by University of Pennsylvania Press (USA) and A&C Black (London UK)

and Artisan Craft Books (Australia). She has contributed articles for Ceramics Monthly, Ceramic Review, Ceramic, Art and Perception,

and others. She was awarded a US Patent for her innovation with

balanced recipes of paperclay and as such was a pioneer in in that

field.

2011/04/24

>> BOOK >> Prop Builders Molding and Casting

Quoted:

The Plug

You can't make a mold until you have a model or a pattern to work from. You can sculpt something out of clay or use an existing object. Sometimes its best to start with an existing object and then make changes by adding clay or other materials and sculpting new features

The Mold

....... latex rubber mold and plaster casting The mold forms a cavity that you fill with something else to make a part. Learn how to work with rigid and flexible molds, from simple one piece open back molds to split or multi part molds to handle undercuts. Work with the following Mold materials:Plaster - Rigid, inexpensive and fast. Many grades of plaster are available, but common "Plaster of Paris" works fine.

Alginate-

Mix powder with water and it sets up fast to form a soft rubbery material that's safe for skin contact. This picks up fine detail and is the only material for making molds from hands feet etc... This is what your dentist uses when he makes an impression of your teeth. It has a short life and must be used quickly.

Latex Rubber-

Thin liquid rubber that is brushed on in layers to build up a skin mold. This material is very stretchy and can be removed from undercuts and other features, but it also picks up fine detail. Latex is often used with a plaster back-up for larger parts.

Silicone Rubber-

More expensive, but it produces a long lasting tough rubber mold that can be poured in thicker sections to create a "Block" mold of an item. Silicone can also be used with a plaster back-up to save on cost.

Moulage-

This is similar to Alginate, but is a lumpy gelatin compound that must be heated to reach pouring consistency.

Mold Releases

Some mold materials are self releasing, but others aren't. If you want to be able to remove your finished casting, then you must use the proper mold release such as Petroleum jelly, Wax, PVA, Green soap, Talc, and sometimes even water.

Making The Castings

More well documented examples of unique casting materials. Learn how to do Absorption Casting with liquid clay in a plaster mold. The plaster absorbs water from the clay, and when you pour out the excess you have a uniform shell. You can also use Neoprene rubber for absorption casting. See how to make a reinforced Latex mold from an uncooked turkey. Learn how to make Laminated Castings with a female mold using Papier Mache, Fiberglass and Celastic which is a plastic filled plastic that's activated by soaking it in acetone.

Work with "Hot Melts and Thermoplastics". Hot Melts, are moldable when heated and solid at room temperature. Some examples are Hot melt glue sticks, Waxes, Plasticine, and hot melt PVC plastic. Again, you get to see an item cast from each material.

Learn how to make "Break Away" glass for window panes and bottles. This book even includes a simple recipe for Sugar Glass that can be mad in your kitchen. A more modern material called "Picco Resin" is more popular than sugar glassand you get detailed instructions on how to cast a window pane and make a fake glass bottle.

contact:

(248) 391-2974

2011/04/20

Jonni Good's Ultimate Paper Mache, clay

It might be a bit more accurate to call this material “home-made air-dried cellulose-reinforced polymer clay,” but that’s way too hard to say (or type!), so for now, let’s just call it paper mache clay.

<a href="http://ultimatepapermache.com/paper-mache-clay">Jonni Good's Paper Mache Book</a>

2011/03/24

paper for molding

There are many different uses for paper. One way people use paper is for paper molding or casting. People pour moist paper into a mold, press the water out using a sponge and let the paper dry.

When the paper is removed from the mold, it is thick and hard. It creates a strong material that can be used for decorating. Producing paper for molding is a quick procedure that requires no experience or special skills. The produced paper can be used for ornaments, jewelry, sculptures or other cast items.

2011/03/19

2006/03/10

2006/02/15

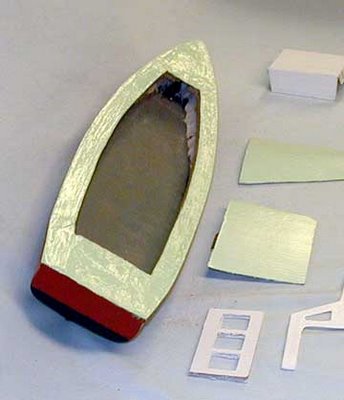

PM hull with sheer strip

2006/02/09

1/24 scale Model of 35 Foot Maine Lobster Boat

To start a plug (aka mold, aka armature) is made from the hull lines of the boat. This one was made to have wooden ribs so there are alignment aides for placing the ribs around the plug. They will not be used for making a PM hull.

The plug is built on a platform that has screws and nails available to enable elastic bands to be strung accross the hull and hold "planking" inplace.

When finished the PM model will be like this wooden model built from the same plug. The difference will be in the hull materials. Instead of gluing wooden planks to ribs the hull will be made from Paper Mache -- layers of cardboard, heavy paper and tissue paper pulp.

2006/01/01

Making Parts, Patterns, Tools, & Molds Video Library

Freeman's video library, featuring over three hours of instructional and product videos, making it the most comprehensive free resource for the making of parts, patterns, tools and molds.

Freeman Mfg & Supply Co.

Freeman is the one-stop

materials supplier to industries that design, develop,

and manufacture products to precise sizes and shapes.